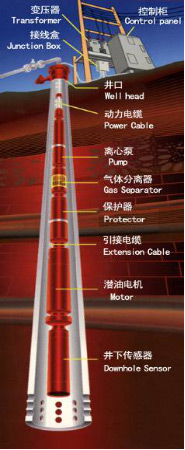

Electrical Submersible Pump System

Electrical Submersible Pump System

PEMSCO could provide 4 series electrical submersible pump systems which are applicable for 4-1/2” to 8-5/8”casing, 30m3/d to 4700m3/d flow rate, 90℃ to 180℃bottom hole temperature and 3500m lifthead to meet the requirements of users. We could also provide the technical services including well selection,pump selection, installation, operation and trouble shooting.

Submersible Pump

Submersible pumps are multistage centrifugal pumps which are designed to lift a full range of volume of oil and water at low operating cost with low initial investment. A pump is composed of impellers, diffusers, shaft, housing, pump head and base. Tandem pumps can be provided to satisfy the higher head requirement.

The submersible pumps are categorized into 86 series, 101 series (98 series), 130 series and 172 series.

Pump Specification

|

Casing |

Series |

OD(mm) |

m3/d @50HZ |

BPD@ 60HZ |

|

4 1/2"Or Large |

86 |

86 |

24-350 |

181-2642 |

|

5 1/2"Or Large |

98 |

98 |

22-900 |

166-6792 |

|

7"Or Large |

130 |

130 |

145-1715 |

1094-12900 |

|

8 5/8"Or Large |

172 |

172 |

1600-5640 |

12076-42569 |

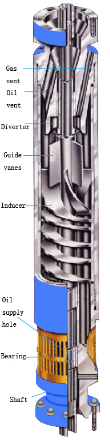

Gas Separator

In high GOR and low-bottom-hole pressure wells, the pump performance will be affected significantly by the free gas. In such cases, the intake section is replaced by a gas separator which removes the free gas from the produced fluid. By venting the free gas to the annulus, the separator prevents gas locking and cavitation, stable motor load and increase running life.

For special well conditions such as corrosive, abrasive or high GOR fluid, different design configuration ofseparators will be offered. Ni-Resist chamber and rotating puts eliminate potential corrosion and sandwear problems. In high GOR wells, we provide tandem separators with 5%-10% gas separation efficiencyincrease.

Three series gas separators are offered: 86 series, 101 series (98 series) and 130 series, to satisfy the necessity of pumps and casings.

Separator Specification

| Casing | Series | Type | Length(m) | OD(mm) |

|---|---|---|---|---|

| 4-1/2"or Large | 86 | QYF86X | 0.65 | 86 |

| 5-1/2"or Large | 98 | QYF98X(17.4) | 0.76 | 98 |

| QYF98X(22.2) | 0.69 | |||

| 101 | QYF101X(17.4) | 0.76 | 101.6 | |

| QYF101X(22.2) | 0.69 | |||

| QYF101XG(17.4) | 0.71 | |||

| QYF101XS(17.4) | 1.22 | |||

| QYF101XS(22.2) | 1.07 | |||

| 7" or Large | 130 | QYF130X | 0.944 | 130 |

| QYF130XS | 1.888 |

Protector

Protector

In general, the protector performs the following basic functions:

a) housing the thrust bearing that carries the axial thrust developed by pump,

b) isolate and protect the motor from well fluid,

c) equalize the pressure inside the motor with the wellbore pressure and thus eliminate the pressure differential across shaft seals,

d) compensate for the expansion and contraction or motor oil due to heating and cooling of the motor when the unit is running or shut down,

e) transmit the shaft torque from motor to pump.

We could provide labyrinth protectors, elastomeric bag/labyrinth protectors and modular design protectors to match individual well conditions or customer requirements.

Five series module protectors are provided by PEMSCO: 86Series, 101 series (98 series),130 series, 143 series and

172 series protectors. Tandem protectors can be used to increase motor protection when needed.

Protector Specification

| Casing | Series | Type | Configuration | Length(m) | OD(mm) | Application Temperature |

|---|---|---|---|---|---|---|

| 4-1/2"or Large | 86 | QYH86J | Elastomeric Bag | 1.6 | 86 | 90/120℃ |

| 4-1/2"Or Large | 86 | Double Elastomeric Bag | Elastomeric Bag | 2 | 86 | 90/120℃ |

| 5-1/2"Or Large | 98 | QYH98RC | Labyrinth | 1.6 | 98 | 90/120℃/150℃ |

| 5-1/2"Or Large | 98 | QYH98J | Elastomeric Bag | 1.7 | 98 | 90/120℃/150℃ |

| 5-1/2"or Large | 86 | QYF86X | Elastomeric Bag | 0.65 | 86 | 90/120℃/150℃ |

| 5-1/2"or Large | 86 | QYF86X | Elastomeric Bag | 0.65 | 86 | 90/120℃/150℃ |

| 7"Or Large | 130 | QYH130C | Labyrinth | 1.9 | 130 | 90/120℃/150℃ |

| 7"Or Large | 130 | QYH130J | Elastomeric Bag | 0.65 | 130 | 90/120℃/150℃ |

| 7"Or Large | 143 | QYH143C | Labyrinth | 1.9 | 143 | 90/120℃/150℃ |

| 7"Or Large | 143 | QYH143J | Elastomeric Bag | 1.9 | 143 | 90/120℃/150℃ |

| 7"Or Large | 130 | QYH130 | Modular Design | 3 | 130 | 90/120℃/150℃ |

| 7"Or Large | 143 | QYH143 | Modular Design | 3 | 143 | 90/120℃/150℃ |

| 8-5/8"or Large | 172 | QYH172C | Labyrinth | 2.1 | 172 | 90/120℃/150℃ |

| 8-5/8"Or Large | 172 | QYH172J | Elastomeric Bag | 2.1 | 172 | 90/120℃/150℃ |

| 8-5/8"Or Large | 172 | QYH172J2 | Double Elastomeric Bag | 2.1 | 172 | 90/120℃/150℃ |

The submersible motor is a two-pole three-phase squirrel cage induction motor with a length varying from 1.5meters to 10 meters. Tandem configuration with higher power output can be provided according to the requirement.

The motor is vertical suspending configuration, and mainly made up of stators, rotors, bearings, head and base. A highly refined mineral oil is filled in the motor inside to provide dielectric strength, lubrication for bearing and cooling.

PEMSCO offers motor designs in a wide range of rated horse Over, operating voltages and currents to meet application requirements in casings of 4-1/2”, 5-1/2”, 7”, 8-5/8”or larger casing size. Normally the operating voltage for motors is from 200V to 3500V, and the operating current is from 10A to 120A. The output horsepower is a direct proportion with the motor length. When the motor is fully loaded, the rotate speed is up to 2900 RPM at 50 Hz.

Motor Specification

|

Casing |

Series |

OD(mm) |

KW 50HZ |

HP 60HZ |

Application Temperature |

||

|---|---|---|---|---|---|---|---|

|

|

|

|

Range |

KW Per Rotor |

Range |

HP Per Rotor |

|

|

4 1/2" Or Large |

95 |

95 |

6-72 |

1.2 |

10-116 |

1.9 |

150℃ |

|

5 1/2" Or Large |

114P |

114.3 |

6-148 |

3.1 |

10-240 |

5 |

150℃ |

|

5 1/2" Or Large |

114J |

114.3 |

7-152 |

3.7 |

10-246 |

6 |

120℃ |

|

5 1/2" Or Large |

114PH |

114.3 |

8-151 |

4.3 |

14-245 |

7 |

90℃ |

|

5 1/2" Or Large |

114Y |

114.3 |

8-152 |

4 |

12-243 |

6.4 |

Rare earth permanent magnet synchronous motor 90℃ |

|

7" Or Large |

138 |

138 |

8-320 |

8 |

26-516 |

12.9 |

150℃ |

|

7" Or Large |

143 |

143 |

10-420 |

10 |

32-672 |

16 |

150℃ |

|

7" Or Large |

143(New type) |

143 |

240-504 |

12 |

386-810 |

19.3 |

120℃ |

|

5/8" Or Large |

188 |

188 |

50-900 |

25 |

643-1448 |

40 |

150℃ |